Inorganic ion capture agent IXE

Conventional organic ion exchange resins have the weaknesses of low heat resistance and poor resistance to organic solvents. Also, clay minerals and zeolite have been known as inorganic ion exchangers for long time. However, they have some weaknesses likepoor reproducibility of functions and lack of water resistance. IXE is a series of inorganic ion exchangers commercialized for the first time in the world by Toagosei to offset the weaknesses of conventional organic and inorganic ion exchangers.

- Product Name

-

IXE

Features

IXE is an ion-trapping agent with superior ion-trapping and heat resistance properties. The reliability of electronic materials can be improved by adding this agent to sealants or other materials.

- Superior heat resistance.

- High ion selectivity; specific ions can be trapped through co-existing ions.

- Effective even in conditions with almost no moisture.

- Superior resistance to organic chemicals and to melting resins.

- High resistance to oxidation, meaning it can be used in oxidized environments.

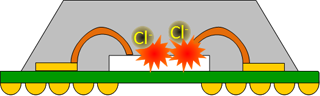

Mechanism of action

The reliability of electronic materials can be improved by adding this agent to trap the ions of impurities in sealants.

Without IXE

With IXE

Usage

- IC encapsulating material (EMC, liquid sealing material, and more)

- FPC adhesives and resist Inks

- Paints (coating film durability, improvement of rust resistance effects)

- Organic solvents, purification of monomers, etc.

Specifications

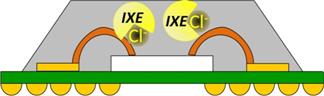

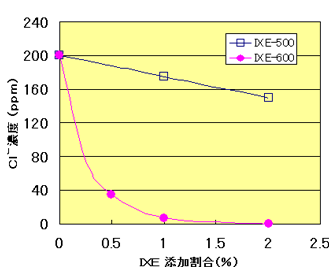

Ion scavenging effect

- IXE is added to IC encapsulants to trap ionic impurities contained in the encapsulant.

- Expected to improve the moisture resistance reliability of ICs.

Pressure cooker test for epoxy resin

Test conditions

- Bisphenol epoxy resin + amine curing agent 100 parts, Ion scavenger 2.0 parts

- Pressure cooker test: 1.0 g of crushed resin / 20 ml of ion-exchanged water, 121°C x 20 hours

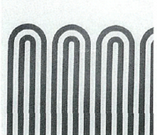

Corrosion and migration suppression of aluminum wiring

- IXE" traps impurity ions in the encapsulating resin and improves the reliability of electronic materials.

- When added to the encapsulating resin, it is expected to suppress corrosion and migration of the wiring.

Corrosion test of aluminum wiring

Additive-free

IXE-770D 0.5 parts

Test conditions

- Bisphenol epoxy resin + amine curing agent 100 parts, Ion scavenger 2.0 parts

- Pressure cooker test: 1.0 g of crushed resin / 20 ml of ion-exchanged water, 121°C x 20 hours

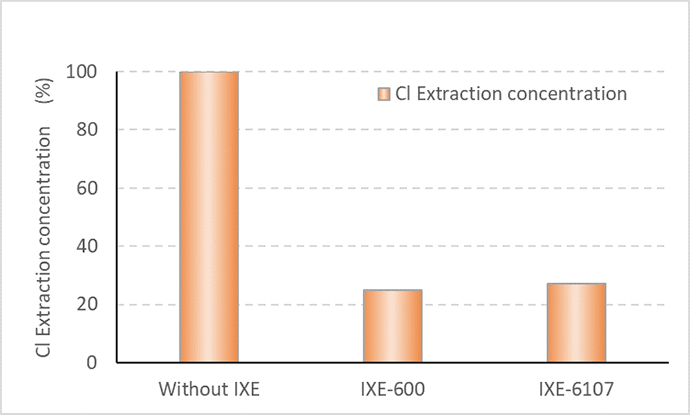

Migration test of aluminum wiring

Without IXE

IXE-500 2.0 parts

Test conditions

- Epoxy acrylate resin 98 parts, IXE-500 2 parts (wiring width 20 μm, spacing 20 μm)

- Unsaturated vapor pressure bias test (121°C, 97%RH, 100 hours)

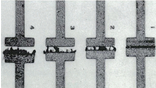

Migration suppression of silver electrode

- Effectively suppresses copper wiring migration.

Copper wiring migration test

No additive

IXE-770D 2.0 part

Test conditions

- Epoxy acrylate + urethane acrylate resin 98 parts, IXE-770D 2.0 parts

- Wiring width 50 µm, wiring spacing 50 µm

- Moisture resistance load test (85℃, 85% RH, 50V, 500 hours)

Migration suppression of silver electrode

- When IXE is added, it is expected to suppress the migration of silver electrodes.

Migration test of silver paste

Without IXE, after 80 hours

IXE-300 5% added, 900 hrs

Test conditions

- Silver paste for CTF, 850°C, 15 min. baking

- 40°C, 95%RH, 100V applied

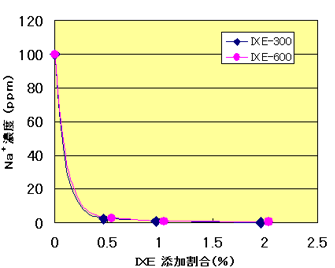

Desalting of organic solvents

- It can selectively capture impurity ions in various chemical solutions.

- Both ion exchangers can reliably capture anions even in the neutral range.

Removal of NaCl in DMF

60°C, 18hrs incubation

Graphs of IXE-300, IXE-600

Graphs of IXE-500, IXE-600

General Characteristics

Related products

Inquiries

- Department in charge

- Inorganic Functional Materials Department

- Phone number

- +81-3-3597-7265

*9:00 am - 5:00 pm (except weekends and holidays)