Inorganic ion capture agent IXEPLAS

IXEPLAS is a higher performance version of IXE, our ion-trapping agent, with superior ion-trapping and heat resistance properties. In addition to increasing the reliability of sealing materials, it can also be used for advanced semiconductor packages.

- Product Name

-

IXEPLAS

Features

Features

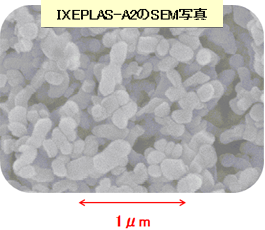

- Its primary particle size is on the sub-micron level and it can be used for underfill materials, narrow pitch sealants, and more.

- The fine particle size makes it highly effective in small quantities.

- It traps copper and silver ions, making it ideal for copper bonding wire, sealing silver wiring, and more.

- Shows ion-trapping capability at a broad pH range because it is a dual ion exchanger.

- With minimal impurities, it has almost no negative effects on sealing materials.

- Contains no substances subject to the Restriction of Hazardous Substances (RoHS) Directive.

Mechanism of action

Image of IXEPLAS ion-trapping

- IXEPLAS's fine particle size makes it effective in smaller quantities compared to IXE.

Usage

- IC sealing material (EMC, liquid sealing material, underfill material, and die bonding)

- FPC Adhesives

- Solar battery materials and components (back sheet, sealing resin)

- Resist inks

- Conductive pastes, etc.

Specifications

General Characteristics

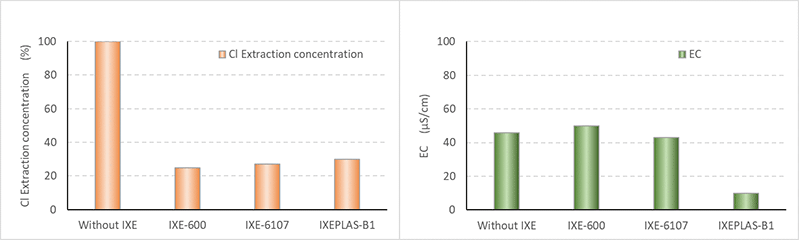

Ion scavenging effect

- IXEPLAS is added to IC encapsulants to trap ionic impurities contained in the encapsulant.

- IXEPLAS emits very few impurity ions.

Pressure cooker test for epoxy resin

Test conditions

- Bisphenol epoxy resin + amine curing agent 100 parts, Ion scavenger 2.0 parts

- Pressure cooker test: 1.0 g of crushed resin / 20 ml of ion-exchanged water, 121°C x 20 hours

Applications

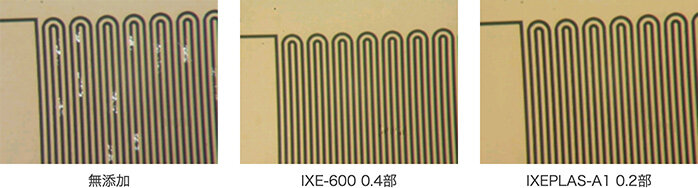

Suppression of copper wiring migration

- IXEPLAS has a high capacity to trap copper ions and is effective in suppressing copper migration.

- It is also ideal for sealing copper bonding wires and copper wiring.

- It can also be used to suppress the migration of silver wiring.

Copper wiring migration test

Test conditions

- Epoxy acrylate + urethane acrylate resin 98 parts, IXEPLAS-A1 1.0 part

- Wiring width 50 μm wiring spacing 50 μm

- Moisture resistance load test (85℃, 85% RH, 50V, 500 hours, 1000 hours)

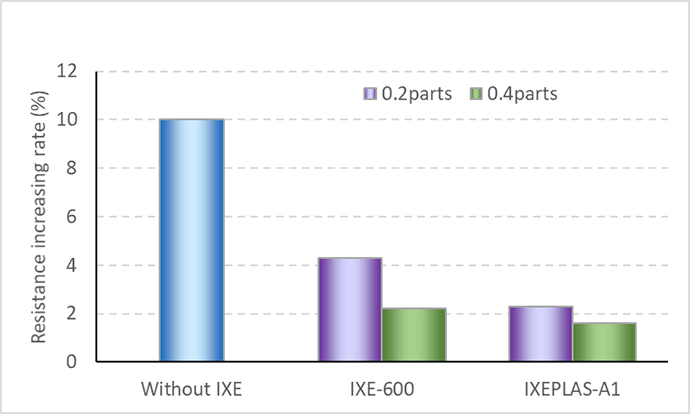

Corrosion inhibition of aluminum wiring

- The addition of IXEPLAS to the encapsulating resin suppresses the corrosion of wiring and improves reliability.

- Because of its fine particle size, a small amount of the product can be effective.

Rate of increase in resistance of aluminum wiring

In semiconductor packages, free Cl- ions in the sealing resin cause corrosion. This causes the resistance of the wiring to increase.

The addition of IXEPLAS traps Cl- ions in the sealing resin, suppressing corrosion and almost eliminating any increase in resistance.

Test conditions

- Adding IXEPLAS to bisphenol epoxy resin, applying and curing to aluminum wiring (wiring width: 20 µm, spacing between wires: 20 µm)

- Pressure cooker test at 130°C, 85%RH, 20V and observe the condition of aluminum wiring after the test (20hr).

Related products

Inquiries

- Department in charge

- Inorganic Functional Materials Department

- Phone number

- +81-3-3597-7265

*9:00 am - 5:00 pm (except weekends and holidays)