ARONIX

We strive for continuous improvement in ARONIX to achieve an excellent balance between industrial development and environmental conservation . We have established technology to completely eliminate toluene from products in promoting manufacturing that is people and earth friendly.

- Product Name

-

ARONIX

Catalog

Catalog Grade

ACRYLATES

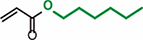

■Mono-functional

| Trade name | Chemical name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration1) | TDS | ||

|---|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

||||||

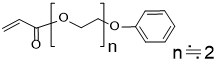

| M-101A | Ethoxylated phenol acrylate |

|

10-20 | -8 | 〇 | 〇 | 〇 | |

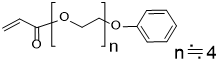

| M-102 |

|

20-40 | -18 | 〇 | 〇 | 〇 | ||

| M-111 | Ethoxylated nonylphenol acrylate | - | 60-90 | 17 | 〇 | 〇 | 〇 | |

| M-113 | - | 80-110 | -20 | 〇 | 〇 | 〇 | ||

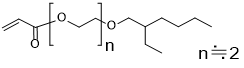

| M-120 | Ethoxylated 2-ethyhexyl acrylate |

|

4-7 | -65 | ✕ | 〇 | 〇 | |

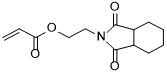

| M-140 | N-[2-(Acryloyloxy)ethyl] phthalimide |

|

350-550 | 56 | LVE | 〇 | 〇 | |

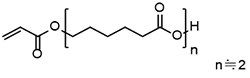

| M-5300 | ω-carboxy-polycaprolactone (n≒2) monoacrylate |

|

80-180 | - | ✕ | 〇 | 〇 | |

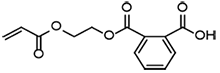

| M-5400 | Acryloyloxyethyl phthalic acid |

|

4.000-7.000 | - | ✕ | ✕ | 〇 | |

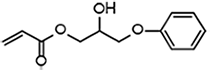

| M-5700 | 2-hydroxy-3-phenoxypropyl acrylate |

|

140-190 | 17 | 〇 | 〇 | 〇 | |

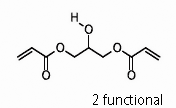

■Bi-functional

| Trade name | Chemical name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration1) | TDS | |||

|---|---|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

|||||||

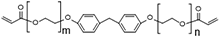

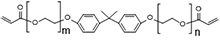

| M-208 | Ethoxylated bisphenol F diacrylate |

|

n≒2 | 500-700 | 75 | ✕ | 〇 | 〇 | |

| M-211B | Ethoxylated bisphenol A diacrylate |

|

n≒2 | 950-1.350 | 75 | 〇 | 〇 | 〇 | |

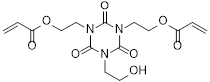

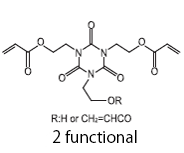

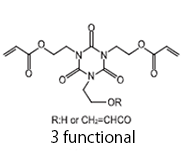

| M-215 THEIC series | Tris (2-hydroxyethyl isocyanurate) diacrylate |

|

N/A | 3.500-15.000 | 166 | 〇 | 〇 | 〇 | |

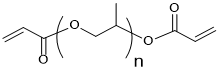

| M-220 PPGDA |

Polypropylene glycol diacrylate |

|

n≒3 | 8-16 | 90 | 〇 | 〇 | 〇 | |

| M-225 PPGDA |

n≒7 | 30-40 | -8 | ✕ | ✕ | 〇 | |||

| M-270 PPGDA |

n≒12 | 65-85 | -32 | ✕ | ✕ | 〇 | |||

| M-240 TEGDA |

Tetraethylene glycol diacrylate |

|

n≒4 | 13-24 | 50 | 〇 | 〇 | 〇 | |

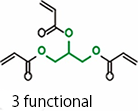

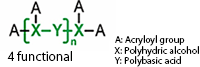

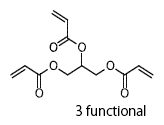

■Multifunctional

TMPTA series

| Trade name | Chemical name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration1) | TDS | ||

|---|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

||||||

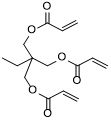

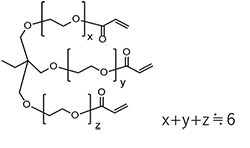

| M-309 TMPTA |

Trimethylolpropane triacrylate |

|

60-110 | 250 or over | 〇 | 〇 | 〇 | |

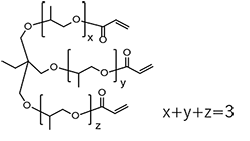

| M-310 POTMPTA |

Propoxylated trimethylolpropane triacrylate |

|

60-110 | 120 | 〇 | 〇 | 〇 | |

| M-321 POTMPTA |

|

70-170 | 50 | 〇 | 〇 | 〇 | ||

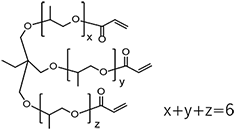

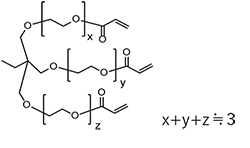

| M-350 EOTMPTA |

Ethoxylated trimethylolpropane triacrylate |

|

45-65 | - | 〇 | 〇 | 〇 | |

| M-360 EOTMPTA |

|

65-90 | 53 | 〇 | 〇 | 〇 | ||

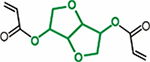

THEIC series

| Trade name | Chemical name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration1) | TDS | |||

|---|---|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

|||||||

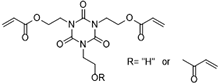

| M-313 | Tris (2-hydroxyethyl isocyanurate) di/triacrylate |

|

di(%) 30-40 |

20.000-36.000 | 250 or over | 〇 | 〇 | 〇 | |

| M-315 | di(%) 3-13 |

N/A | 250 or over | 〇 | 〇 | 〇 | |||

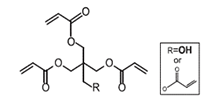

PETA series /PETTA series

| Trade name | Chemical name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration1) | TDS | |||

|---|---|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

|||||||

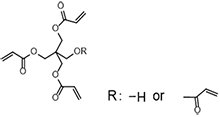

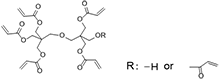

| M-306 PETA |

Pentaerythritol tri/tetraacrylate |

|

tri(%) 65-70 |

400-650 | 250 or over | 〇 | 〇 | 〇 | |

| M-305 PETA |

tri(%) 55-63 |

180-800 | 250 or over | 〇 | 〇 | 〇 | |||

| M-305 PETA |

tri(%) <10 |

N/A | 250 or over | 〇 | 〇 | 〇 | |||

DTMPTA

| Trade name | Chemical name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration1) | TDS | ||

|---|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

||||||

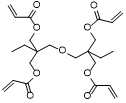

| M-408 DTMPTA |

Ditrimethylolpropane Tetraacrylate |

|

470-670 | 250 or over | 〇 | 〇 | 〇 | |

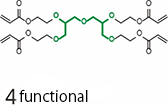

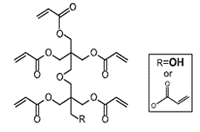

DPHA series

| Trade name | Chemical name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration1) | TDS | |||

|---|---|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

|||||||

| M-400 DPHA |

Dipentaerythritol Penta- and Hexaacrylate |

|

Penta (%) 40-50 |

(or Solid) 5.000-7.000 |

Over 250 | 〇 | 〇 | 〇 | |

| M-402 DPHA |

Penta (%) 30-40 |

(or Solid) 5.000-7.400 |

250 or over | 〇 | 〇 | 〇 | |||

| M-404 DPHA |

Penta (%) 30-40 |

4.500-7.000 | 250 or over | 〇 | 〇 | 〇 | |||

| M-406 DPHA |

Penta (%) 25-35 |

(or Solid) 6.800-9.800 |

250 or over | 〇 | 〇 | 〇 | |||

| M-471 DPHA |

Penta (%) 20-40 |

(or Solid) 6.500-8.500 |

250 or over | 〇 | 〇 | 〇 | |||

| M-405 DPHA |

Penta (%) 10-20 |

3.700-5.700 | 250 or over | 〇 | 〇 | 〇 | |||

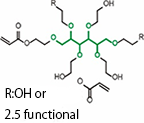

Polybasic acid modified products

| Trade name | Chemical name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration1) | TDS | ||

|---|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

||||||

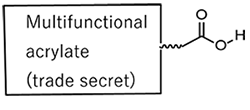

| M-510 | PCarboxyl-modified multifunctional acrylate |

|

3.500-6.500 | N/A | ✕ | 〇 | 〇 | |

| M-520 | (or Solid) 11.500 - 16.500 |

N/A | ✕ | 〇 | ✕ | |||

| M-521 | (or Solid) 40.000-46.000 |

N/A | ✕ | 〇 | ✕ | |||

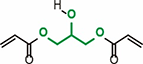

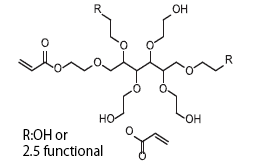

Ethoxlylated diglycerol acrylate product

| Trade name | Chemical name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration1) | TDS | ||

|---|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

||||||

| M-460 | Ethoxlylated diglycerol tetracrylate |

|

200-500 | N/A | ✕ | ✕ | ✕ | |

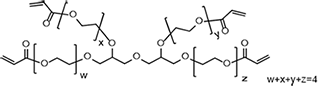

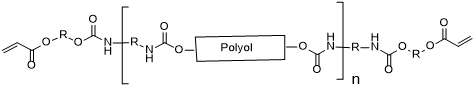

Urethane acrylate

■Bi-functional

| Trade name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration | TDS | ||

|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

|||||

| M-1100 |

|

N/A | 47 | 〇 | 〇 | 〇 | |

| M-1200 | N/A | 35 | 〇 | 〇 | 〇 | ||

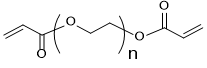

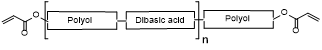

Polyester acrylates

■Bi-functional

| Trade name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration | TDS | ||

|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

|||||

| M-6100 |

|

200-450 | 29 | 〇 | 〇 | 〇 | |

| M-6250 | 300-700 | 45 | 〇 | 〇 | 〇 | ||

| M-6500 | 300-500 | 40 | 〇 | 〇 | 〇 | ||

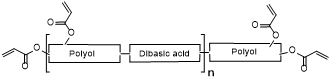

■Multi-functional

| Trade name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration | TDS | ||

|---|---|---|---|---|---|---|---|

| US TSCA |

KR ECL |

CN IECSC |

|||||

| M-7100 |

|

8.000-13.500 | 105 | 〇 | 〇 | 〇 | |

| M-7300K | 2.000-3.000 | 250 or over | ✕ | ✕ | 〇 | ||

| M-8030 | 560-960 | 250 or over | 〇 | 〇 | 〇 | ||

| M-8060 | 5.000-12.000 | 250 or over | 〇 | 〇 | 〇 | ||

| M-8100 | 8.000-12.000 | 163 | 〇 | 〇 | 〇 | ||

| M-8530 | 350-650 | N/A | 〇 | 〇 | 〇 | ||

| M-8560 | 3.400-7.400 | N/A | 〇 | 〇 | 〇 | ||

| M-9050 | 6.000-14.000 | 300 or over | ✕ | ✕ | 〇 | ||

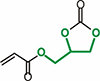

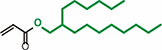

Biomass acrylate

SQP:New chemicals Small volume

(less than 1 ton release amount to environment)

| Trade name | Chemical name | Chemical structure | Biomass content (%) | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration | |||

|---|---|---|---|---|---|---|---|---|---|

| JP | US TSCA |

KR ECL |

CN IECSC |

||||||

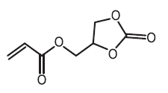

| M-910(Mono-functional) | Glycerol Carbonate Acrylate |

|

53 | 40-80 | 71 | SQP | ✕ | ✕ | ✕ |

| MT-1519(Mono-functional) | l-Menthyl acrylate |

|

73 | 1-10 | 40 | SQP | ✕ | ✕ | ✕ |

| MT-1522(Mono-functional) | 2-Hexyldecyl acrylate |

|

81 | 1-10 | -85 | 〇 | ✕ | ✕ | ✕ |

| MT-1523(Mono-functional) | n-Hexyl acrylate |

|

64 | 1-5 | -60 | 〇 | 〇 | 〇 | 〇 |

| M-920(Bi-functional) | Glycerin diacrylate |

|

45 | 40 | N/A | 〇 | ✕ | ✕ | 〇 |

| MT-2545(Bi-functional) | Isosorbide diacrylate |

|

57 | 100-500 | N/A | SQP | ✕ | ✕ | ✕ |

| M-460(Multi-functional) | Glycerin triacrylate |

|

30 | 200-500 | N/A | 〇 | ✕ | ✕ | 〇 |

| M-930(Multi-functional) | Glycerin triacrylate |

|

37 | 30 | N/A | 〇 | 〇 | ✕ | 〇 |

| M-926(Multi-functional) | Ethoxlylated sorbitol acrylate |

|

27 | 4,000 | 53 | 〇 | ✕ | ✕ | 〇 |

| OT-3538(Polyester) | Multifunctional polyester acrylate |

|

33 | 500-1,000 | N/A | SQP | ✕ | ✕ | ✕ |

Toluene-free acrylate

| Trade name | Chemical name | Chemical structure | Viscosity (mPa-s) 25°C | Tg (℃) |

Registration1) | |||

|---|---|---|---|---|---|---|---|---|

| JP | US TSCA |

KR ECL |

CN IECSC |

|||||

| M-920(Bi-functional) | Glycerol diacrylate |

|

40 | N/A | 〇 | ✕ | ✕ | 〇 |

| M-930(Multi-functional) | Glycerin triacrylate |

|

30 | N/A | 〇 | 〇 | ✕ | 〇 |

| M-934(Multi-functional) | Pentaerythritol tri/tetraacrylate (High hydroxyl value) |

|

450 | 250 or over | 〇 | ✕ | ✕ | 〇 |

| M-933(Multi-functional) | 550 | 250 or over | 〇 | ✕ | ✕ | 〇 | ||

| M-940(Multi-functional) | Dipentaerythritol penta/hexaacrylate (High hydroxyl value) |

|

3,500 | 250 or over | 〇 | 〇 | 〇 | 〇 |

| M-923(Multi-functional) | TTris (2-hydroxyethyl isocyanurate) di/triacrylate |

|

70,000 | 181 | 〇 | 〇 | 〇 | 〇 |

| M-935(Multi-functional) | Tris (2-hydroxyethyl isocyanurate) di/triacrylate |

|

1,000 (50℃) |

250 or over | 〇 | 〇 | 〇 | 〇 |

| M-910(Mono-functional) | Glycerin carbonate acrylate |

|

40-80 | 71 | SQP | ✕ | ✕ | ✕ |

| M-926(Multi-functional) | Ethoxlylated sorbitol acrylate |

|

4,000 | 53 | 〇 | ✕ | ✕ | 〇 |

- A circle(〇) symbol represents that a reference has been confirmed. A cross(×) symbol represents that there is no reference or that the refereence has not been confirmed.

Our checks have been performed with the utmost care but we ask that you perform your own checks before use.

New Development Grade

Monomers & Oligomers (M Series)

| No. | Name | Characteristics & Usage |

|---|---|---|

| 1 | Low viscosity, high hardness, adhesion, hard coat | |

| 2 | Raw material for high hardness, toughness, low curl, multifunctional urethane acrylate | |

| 3 | Low viscosity, high hardness, hard coat | |

| 4 | Adhesion of glass, PET, polyimide, metal, polycarbonate, TAC, primer | |

| 5 | LED fast curing (high sensitivity), high hardness, good heat stability |

UV-series

| No. | Name | Characteristics & Usage |

|---|---|---|

| 1 | Solventless & low viscosity, spray, inkjet, nanoimprint, surface imprinting, transfer resin | |

| 2 | Weather resistance (abrasion resistance, color difference), adhesion |

Sheet series (glass substitute, LiDAR)

| No. | Name | Characteristics & Usage |

|---|---|---|

| 1 |

High transparency, high heat resistance, high hardness, low phase difference, high chemical resistance, high processability Transparent sheets for display covers and laboratory process inspections |

|

| 2 |

High optical performance (transmits approx. 90% of near-infrared rays at 950 nm and 1550 nm) High heat resistance, high hardness, low phase difference, high chemical resistance, high processability Sensor covers for automotive, smartphones, drones, and industrial robots |

|

| 3 | LiDAR, filter |

Features

Features of ARONIX

- Eco-friendly products (solvent free)

- Energy saving and increased production speed

- Wide range of product designs

Usage

Use as UV-curable materials

- Light-curable inks and paints

- Electron beam curable paints

- Light-curable adhesives

- Resist materials

Epoxy resin modification

- Amine curable epoxy resin modification

Plastic cross-linker, modification agent

Specifications

ARONIX curing methods

Typical methods of curing ARONIX are as follows.

| Curing methods | Example of catalyst system | |

|---|---|---|

| Radical polymerization | Heat-curing Thermal oven, far infrared, microwave |

Add benzoyl peroxide, dicumyl peroxide, etc. as the catalyst (radical initiator). |

| Redox-based room temperature curing | Add benzoyl peroxide, dimethylaniline, cumene hydroperoxide, vanadium-based accelerator, etc. | |

| Anaerobic curing | Add hydroperoxide, tertiary amine, sulfimide, etc. | |

| UV-curing | Add a photoinitiator (such as benzoyl alkyl ether, benzophenone, or acetophenone) | |

| Electron beam curing | (no catalyst added) | |

| Michael addition | Room temperature, heat-curing | Add a polyamine possessing a primary or secondary amino group. |

ARONIX and ARON Oxetane are for industrial use. Consult the product safety data sheet (SDS) to ensure you understand the risks and take proper health and safety measures and environmental measures.

Contact us if you have any questions.

Handling Precautions

Exposure of ARONIX, special acrylic monomer and oligomer product, to the skin, eyes, or mucous membranes may trigger rashes, inflammation, and allergic reactions.

- Ensure proper ventilation

Generally, it has a high boiling point and low volatility, therefore there is almost no damage to the skin caused by steam at room temperature. However, steam may occur during heating or UV-curing. Ensure proper ventilation in the work space.

- Wear appropriate protective equipment

- Wear protective equipment such as gloves, apron, and safety goggles to avoid contact of the substance with the skin, and do not handle with bare hands.

- If wearing protective gloves, make sure the contaminated gloves do not touch the skin.

- Natural rubber is an effective material for the protective gloves. Vinyl gloves may allow the material to penetrate and are not suitable.

- Promptly rinse under water if the product comes in contact with the skin.

Be very careful of skin contact as the liquid is clear and does not cause irritation when initially exposed to the skin.

Rinse with soap water immediately as long term contact with skin can cause skin damage.

Avoid washing with solvents, as they will speed up penetration of the material into the skin.

In case of skin contact, inhalation or ingestion of the material, seek medical attention and treatment even without subjective symptoms.

- If the product gets in contact with the eyes, immediately rinse with plenty of water for at least 15 minutes and seek medical attention from an ophthalmologist.

- If inhaled, relocate to a place with fresh air to rest and seek medical attention immediately.

- Seek medical attention immediately if ingested.

* In the event of a fire, wear protective equipment (and a respirator if necessary) to extinguish the fire from upwind using powder, foam or carbon dioxide fire extinguisher.

*As a highly reactive substance, polymerization will occur as a result of exposure to light, impact, heat, and mixing with other substances, which can lead to sudden heating, damage and breakage of containers. Use upon confirming the reactivity in advance.

*In case of a spill from the container, remove sources of heat and ignition from its surrounding, and use paper towel or sand and gravel to recover the spillage in an empty container if the amount is small, then rinse the area with plenty of water. If there is a large amount of spill, enclose it in embankment to stop the outflow and collect it in a closed container. Handle while wearing protective equipment.

*Contact a waste material processor for disposal.

Storage method

Store following the regulations stipulated by applicable laws and regulations such as the Fire Service Act.

- Avoid hot objects, sparks and open flames, and do not store in the same place as oxidizing materials and peroxides.

- Store well sealed in a well ventilated, cool, and dark location (30℃ or under) and avoid direct sunlight.

- Keep electrical equipment in the storage location in an explosion-proof structure, and ground the equipment.

- Do not transfer to other containers.

Overseas expansion

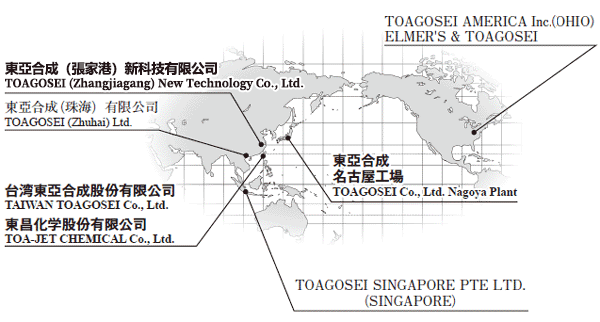

Toagosei manufactures ARONIX at its Nagoya Plant as the main site of production. For overseas locations, we established a sales location in Taiwan in 2000 (TAIWAN TOAGOSEI Co., Ltd.) and a began manufacturing in 2001 (TOA-JET CHEMICAL Co., Ltd.). Furthermore, we established a new company in Zhangjiagang, Jiangsu, China in 2004 (TOAGOSEI (Zhangjiagang) New Technology Co., Ltd.) to conduct manufacturing and sales, which began operations in 2005.

Inquiries

- Department in charge

- POLYMER & OLIGOMER DIVISION OLIGOMER DEPARTMENT

- Phone number

- +81-3-3597-7332

*9:00 am - 5:00 pm (except weekends and holidays)