Silsesquioxane Derivative

The UV-curable SQ Series is an organic-inorganic hybrid material that combines an inorganic backbone with UV-curable organic functional groups at the molecular level. It is developed as a material for hard coats, sealants, heat resistant, and glass replacement. We offer a lineup of products that utilize radical polymerization and cationic polymerization.

Features

What is silsesquioxane?

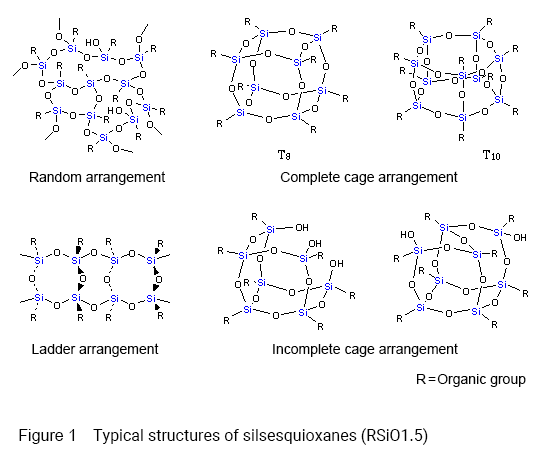

Silsesquioxane (SQ) is a siloxane compound with the chemical formula [(RSiO1.5)n]. Its main chain backbone is composed of Si-O bonds. The 1.5 in unit composition formula refers to the siloxane having one and a half oxygen (1.5 = sesqui). For this reason, the compound is named Sil-sesqui-oxane. As expressed by its composition [(RSiO1.5)n], SQ can be considered as an intermediate substance between inorganic silica [SiO2] and organic silicon [(R2SiO)n]. Given this intermediary status, SQ delivers heat resistance, hardness, and other inorganic features as well as the softness, solubility, and other organic features. In contrast to the insolubility of silica, which is a pure inorganic material, SQ dissolves homogeneously with general use resins, and therefore, it can simplify processes such as resin compounding, mixing, processing and forming. SQ can form many different types of backbone structures, with reported shapes including cage, ladder, and random structures (Fig. 1). The structural appearance of SQ demonstrates its composition of both organic units and inorganic units (SQ backbone) at the molecular level. It is possible to introduce various organic functional groups to the SQ backbone, providing the potential of designing materials that reflect the functions of those groups. Owing to these features, SQ has attracted attention in recent years as a new organic-inorganic hybrid material capable of advanced functions.

What is the UV-curable SQ Series?

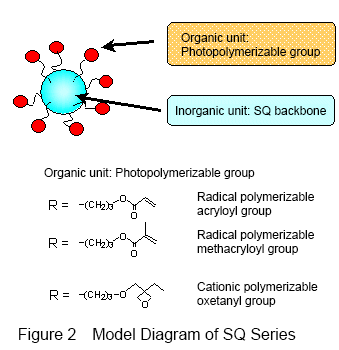

The UV-curable SQ Series represents a new type of organic-inorganic hybrid material with photopolymerizable group (organic unit) introduced to the SQ backbone (inorganic unit) (Figure 2). As for photopolymerizable groups, we offer acryloyl groups (AC) and methacryloyl groups (MAC) for radical polymerization or oxetanyl groups (OX) for cationic polymerization. The SQ backbone takes on random arrangement, cage arrangement and others as mentioned above.

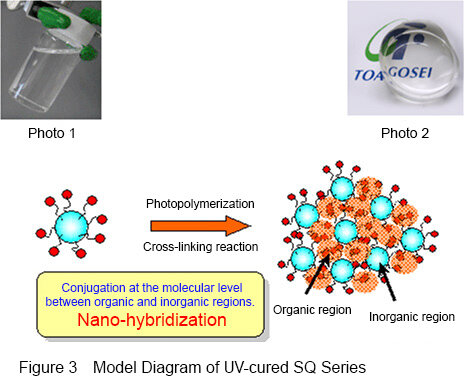

The SQ Series cures well with light or heat when combined with an initiator. Its appearance before curing is a colorless, transparent viscous liquid (Photo 1). A model of UV-curable SQ Series is shown in Fig. 3. It is believed that as the photopolymerizable groups react and intermolecular cross-linking (curing) takes place, an organic-inorganic nano-hybrid structure, where organic regions and inorganic regions are conjugated at the molecular level, is formed. Consequently, the cured material yields characteristics such as high hardness, high transparency (Photo 2), high heat resistance, and high weatherability.

Features of the SQ Series

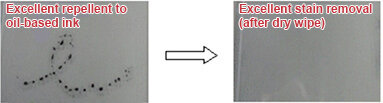

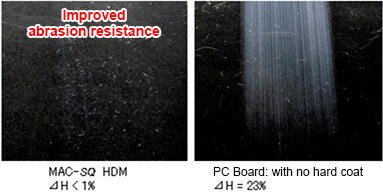

Table 1 shows the features of each of the grades in the SQ Series. We offer radical curable types of AC-SQ and MAC-SQ, and cation curable type of OX-SQ. The curing process can be initiated by adding a photoradical initiator or cation initiator, respectively. We also offer the unique SI grade, which has polydimethylsiloxane (silicone) units incorporated in a portion of the SQ backbone. This imparts the physical properties of silicone to the surface of the resulting cured film, including effective repulsion of oil-based inks (Photo 3). In addition, we have also developed hard coat grades (MAC-SQ HDM, OX-SQ HDX) that greatly improve resistance to abrasion (Photo 4) by increasing the ratio of inorganic contents.

Table 1. Features of the SQ Series

| Grades | Common features | Individual features | |

|---|---|---|---|

| Radical cured | AC-SQ TA-100 |

|

|

| MAC-SQ TM-100 | |||

| AC-SQ SI-20 |

|

||

| MAC-SQ SI-20 | |||

| MAC-SQ HDM (solution) |

|

||

| Cation cured | OX-SQ TX-100 |

|

|

| OX-SQ SI-20 |

|

||

| OX-SQ HDX (solution) |

|

*1 Td5: Temperature of 5% mass reduction of cured products

*2 Cold rolled steel plate: SPCC-SD (JIS G 3141:2005), with zinc phosphate surface treatment

Photo 3 Surface physical properties of SI-20 coated film (contamination resistance test)

Photo 4 Test sample in steel wool abrasion test

Usage

Usage of the SQ Series

- Hard coat material

- Modification additive, strengthener, and heat resistance modifier for a variety of high polymer materials

- Cross-linking agent

- Protective films for various substrates

- Modification additive for a variety of coating materials as well as raw materials for coating materials

- Contamination resistant coating (SI Grade)

- Base material for composite materials of various polymers

- Low-permittivity materials and insulating film materials

- Base material for LED sealants

- Material for optical wave guides

- Sealing materials for semiconductors

- Resist materials and hard mask materials

- Other optical and electronic materials

References

- Ito, Maki. The Chemistry and Application Development of Silsesquioxane Materials. CMC Publishing Co., Ltd. (2007) p. 150.

- Convertech. Converting Technical Institute. 6, 97 (2008).

- Keiso Kagaku Kyokai Shi. Society of Silicon Chemistry. 30, 26 (2013).

- Ito, Maki. The Latest Technologies and Applications for Silsesquioxane Materials. CMC Publishing Co., Ltd. (2013) p. 242.

*The data included in these documents are examples of actual measured values, not standard values. The content of these technical documents is subject to change without notice due to quality improvements or changes in specifications.

*Before using these materials, be sure to conduct tests to confirm that the materials are appropriate for your purpose.

*We cannot guarantee that the applications included in these technical documents do not infringe upon any patents.

*The products included in these technical documents are intended for industrial use. These products should only be used in medical or other special applications after confirming their safety at your own facility. Further, these products are not to be used for any applications where the materials are implanted or injected internally, or applications which run the risk of leaving behind a portion of the materials in the body.

*Please contact us at the number below before reproducing the data in these technical documents.

Specifications

Liquid properties of SQ series

Cured Material Properties of SQ Series

The cured material properties of the SQ series when light-cured with a light curing agent, etc., are shown below.

*Specifications are subject to change without notice.

Inquiries

- Department in charge

- New Products Development Div.