ARONCOAT SQ

ARONCOAR SQ Construction

A unique waterproofing for flat and pitched roofs that can also be used as an overlay for asphalt roofs and waterproofing exposed asphalt

ARONCOAT SQ is a roof waterproofing coated film that uses an acrylic rubber system with two reactive ingredients. In addition to the features of conventional coated film waterproofing, it is exceptionally durable, eco-friendly and reliable. The high performance is officially recognized by obtaining "Construction Technology Examination and Certification Project" by a third-party organization.

- Product Name

-

ARONCOAT SQ

Features

What is ARONCOAT SQ?

ARONCOAT SQ is a waterproofing membrane for roofing that uses an acrylic rubber system with two reactive water-soluble ingredients.

In addition to the features of conventional membrane waterproofing, such as lightweight and seamless coverage of complex areas, ARONCOAT SQ delivers exceptional environmental performance and reliability.

Ecology

Is it eco-friendly?

ARONCOAT SQ is an eco-friendly waterproofing material.

A water-soluble waterproofing material that does not produce foul odors or fumes

ARONCOAT SQ is a solvent-free water-soluble waterproofing material that consists of ARONCOAT SQ Base, a cation-based acrylic rubber emulsion, and ARONCOAT SQ Setter, an inorganic curing agent. Because of its water-soluble composition, ARONCOAT SQ does not emit VOCs into the air. Furthermore, no flame is required, eliminating foul odors and dangerous fumes, Moreover, no noise or vibration is caused by its application.

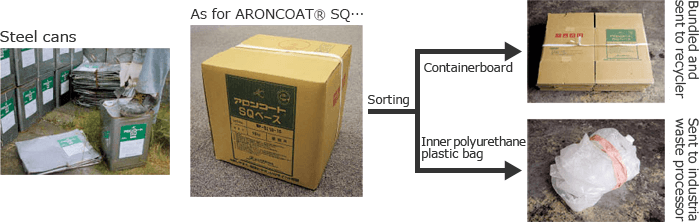

Eco-friendly container resulting in less industrial waste

ARONCOAT SQ Base comes in a containerboard package made primarily from recycled material to help reduce industrial waste.

- ARONCOAT SQ Base is double packaged in containerboard with an inner polyurethane plastic bag with dispenser.

- After use, the inner polyurethane plastic bag is removed and the containerboard recycled.

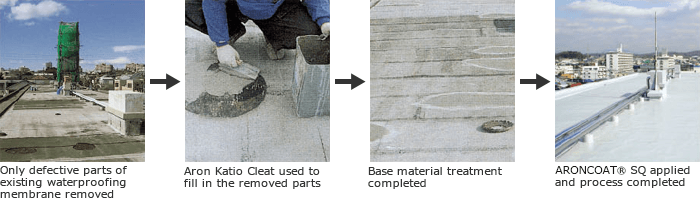

Waterproofing method that results in less industrial waste

ARONCOAT SQ can minimize the removal of existing waterproofing membrane at the time of improvement work.

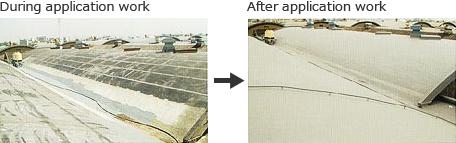

Example improvement work on exposed sand asphalt waterproofing material (overlay application)

Versatility

Can ARONCOAT SQ be used on any roof?

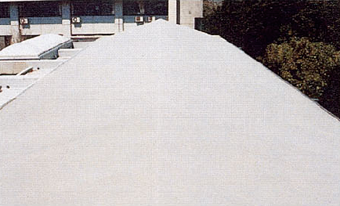

ARONCOAT SQ can be used on a wide range of roof types and shapes, from pitched roofs to domed roofs, regardless of whether it is a new construction or an improvement project.

Example of application on pitched roof

Example of application on domed roof

Can the roof be repaired without removing the existing waterproofing membrane?

ARONCOAT SQ is suited for overlay applications where the existing waterproofing membrane is left in place.

Compatible with various existing waterproofing membranes (completed third-party construction technology review and certification)

Contact us for details.

Ideal for improvement work on exposed sand asphalt waterproofing

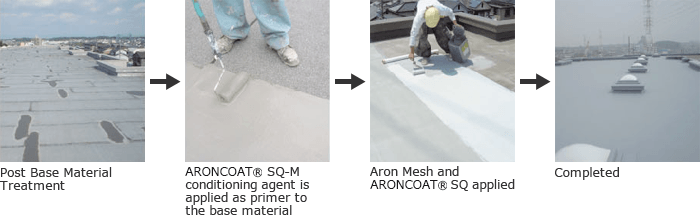

Use the adhesion method to increase cost performance when improving exposed sand asphalt waterproofing materials.

Example improvement work on exposed sand asphalt waterproofing material (SQ-M)

Can ARONCOAT SQ be applied to areas that are difficult to cover?

ARONCOAT SQ can easily be applied seamlessly to complex areas and shapes, delivering reliable waterproofing without the use of metal fittings or other hardware.

Long life

Is ARONCOAT SQ long-lasting?

ARONCOAT SQ offers exceptional durability since its waterproofing membrane maintains the same performance more than 10 years after application. ARONCOAT SQ can also be applied in layers to restore its waterproofing performance.

What should I do in case of a flaw during application?

Even if a flaw occurs, ARONCOAT SQ makes it possible to easily identify the location and make a simple partial repair.

Applied in 1987 (17 years): SQ-K (RC)-L

Applied in 1988 (16 years): SQ-S (RC)-L

Light weight

Does ARONCOAT SQ affect a building's load?

ARONCOAT SQ's waterproofing membrane is light weight and has no impact on a building's load.

ARONCOAT SQ weighs less than 5 kg per square meter applied, including general base material treatment. This ensures any impact on a building's load is minimal.

Quality

How is your quality control system for ARONCOAT SQ?

Our ISO 9001 and ISO 14001 certified manufacturing facility engages in eco-friendly integrated production, beginning with the raw materials.

Do you have an installation system and after-sales service?

Be rest assured

that ARONCOAT SQ is included as part of a responsible installation system by providers.

ARONCOAT SQ is applied responsibly by more than 200 highly specialized and qualified members of the Japan ARONCOAT/ARONWALL Waterproofing Contractors Association.

Is ARONCOAT SQ certified?

ARONCOAT SQ has passed a third-party construction technology review and certification process*1.

ARONCOAT SQ delivers waterproofing performance that equals or surpasses the "X-1" and "X-2" urethane system coated film waterproofing materials listed in the Standard Specifications for Public Works Construction compiled by the Government Buildings Department, MLIT (FY2004 Ver.)

*1: Construction technology review and certification is performed in order to foster private-sector R&D, properly and quickly implement novel construction technologies and to contribute to the advancement of construction technologies.

Do you have an R&D system?

Toagosei actively conducts joint research with universities on waterproofing materials and how to extend the lifespan of buildings.

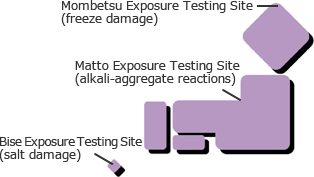

As a pioneer in acrylic rubber, Toagosei engages in joint research with universities in Japan and overseas. We also conduct testing in Hokkaido and Okinawa in order to find ways to extend the lifespan of buildings. This includes testing methods to prevent freeze damage, salt damage and alkali-aggregate reactions.

As a pioneer in acrylic rubber, Toagosei engages in joint research with universities in Japan and overseas. We also conduct testing in Hokkaido and Okinawa in order to find ways to extend the lifespan of buildings. This includes testing methods to prevent freeze damage, salt damage and alkali-aggregate reactions.

Usage

Waterproofing of flat roofs, pitched roofs and domed roofs on buildings and other structures

Examples of Use

ARONCOAT SQ roof repair method

Asphalt and sheets are commonly used to waterproof roof. In recent years, waterproofing by film coating in renovation work has become more common, while urethane rubber-based film coatings are known for being waterproof. However, urethane rubber has weak chemical bonding energy and easily deteriorates in physical properties; therefore, it requires continuous, proper maintenance of the top coat (reapplication every five to six years).

On the other hand, ARONCOAT SQ, which falls under the same category as film coating waterproofing, uses acrylic rubber film coating with waterproofing performance, high weatherability and durability. It has demonstrated in an actual on-site survey, where the film was sectioned off, its waterproof performance did not deteriorate after more than 10 years. Also, the technical inspection certification received from the Building Center of Japan confirms that the waterproofing performance of the product is the same as or higher than urethane rubber. It can be applied to various roof shapes, including pitched roofs and metal domes, and is suitable for covering existing waterproofing layers without removal during repair work. It is also ideal for exposed sand asphalt waterproofing and repairing asphalt shingle roofs.

Another consideration is that the material is completely water-soluble, which includes zero solvent from base repair material to top coat. As a result, no VOCs are released during application. As there is no emission of foul odor or smoke, and it produces minimal noise and vibration during application, ARONCOAT SQ has little impact on residents during repair work for multi-unit residential buildings. For the major repair project of Koriyama General Gymnasium , work was performed on areas damaged in the Great East Japan Earthquake as well as based on the Koriyama City-Kaiseizan District Urban Redevelopment Project. ARONCOAT SQ was selected for the overlay method since it produces less industrial waste from the roof. Instead of removing the entire existing roof covered in exposed sand asphalt waterproofing, only areas with deficiencies were repaired.

With steel plate roofs, even though folded plates and tiles can be used to reduce the load placed on the roof, they are constantly exposed to causes of corrosion as well as significant expansion and contraction due to temperature changes. This makes thin and hard rust-proof paints prone to cracking and peeling, which often become an area where rust starts to spread. Moreover, steel plate roofs make the indoor temperature rise quickly. With an application of ARON QD BOSEI COAT with heat-shield, which uses a rust-proof, waterproof acrylic rubber-based waterproofing material and a finishing coat with high solar reflectance, such challenges of steel plate roof can be addressed with generally 2 kg/m2 of coating, including underlay treatment, without increasing the load on the structure.

Examples of ARONCOAT SQ application

Koriyama General Gymnasium

| Location | Koriyama City, Fukushima Prefecture |

|---|---|

| Completed | 2013 |

| Design | Yoshio Endo Architectural Design |

| Existing design | Flat roof (exposed sand asphalt waterproofing) |

| Reason for use | The contractor selected SQ-M METHOD for its cost performance, shortened work time, and reduced industrial waste. |

Asphalt single thatched roof

| Location | Minato Ward, Tokyo |

|---|---|

| Completed | 2010 |

| Existing design | Pitched roof (asphalt shingle) |

| Reason for use | The contractor selected SQ-AS METHOD for its excellent cost performance and ability to maintain the appearance of asphalt shingles. |

Kisogawa Logistics Center of Meiko Kaiun Kosan Co., Ltd.

| Location | Ichinomiya City, Aichi Prefecture |

|---|---|

| Completed | 2013 |

| Existing design | Folded-plate roof (general rust proof paint) |

| Reason for use | The contractor chose flexible ARON QD BOSEI COAT heat-shield type for water-leakage and heat-shielding capability leading to energy saving on air conditioners. |

The durability of ARONCOAT SQ has been validated 15 years after application.

Toagosei conducts age-related degradation surveys on properties where its products were used in order to verify their performance. Let's take a look at one example.Kyushu and Okinawa are prone to typhoons and there have been many incidents of waterproofing sheets being blown away by strong wind. For this reason, there are high expectations among building designers for ARONCOAT SQ's adhesion method of waterproofing with a coating film. In order to validate the product's durability, surveys were conducted on site in Kyushu and Okinawa 13 to 16 years post application at a total of 6 locations, including exterior inspections. Also, a portion of the coating film was removed to examine the adhesive strength, crack coverage and change in fatigue resistance over time (2007). The result confirmed that ARONCOAT SQ withstood the harsh weather conditions of strong rain and wind and maintained its performance for 15 years without deterioration.

Typically, condominiums require large scale improvement work 13 years after construction, while roof waterproofing is also expected to be replaced at the same time. ARONCOAT SQ, which is capable of maintaining waterproofing performance for more than 13 years, is a superior waterproofing material from the life cycle cost perspective.

ARONCOAT SQ durability test (conducted in 2007)

| Property name | Classification | Years lapsed | Sample film thickness (mm) | Zero span tension elongation |

|---|---|---|---|---|

| Facility A | New construction |

15.5 years | 1.6 | Intact part: 4.2 mm |

| Elementary School B | Renovated | 16.5 years | 2.1 | Intact part: 4.2 mm |

| Junior High School C | Renovated | 15.5 years | 1.7~1.8 | Intact part: 6.6 mm (Damaged protective layer: 4.8mm) |

| Junior High School D | Renovated | 15.5 years | 1.5~1.6 | Intact part: 4.2 mm (Damaged protective layer: 2.4 mm) |

| Center E | New construction | 16 years | 1.2~1.4 | Intact part: 4.1 mm (Damaged protective layer: 3.4 mm) |

| Daycare F | New construction | 13.5 years | 1.7 | Intact part: 5.0 mm |

| Initial coating | 1.9 | 12.1mm | ||

Measurements were taken by the Japan Paint Inspection Association in 2007. The zero span tension elongation was reduced by half compared to the initial coating, but the intact part and damaged protective layer were maintained at 4.1 mm and 2.4 mm, respectively.

Toagosei conducted a survey of six properties for which between 13 and 16 years have passed since the application.

An elementary school in Yamaga City, Kumamoto Prefecture (application in 1990)

A daycare in Naha City, Okinawa Prefecture (application in 1993)

Age-related degradation survey 15 years after application

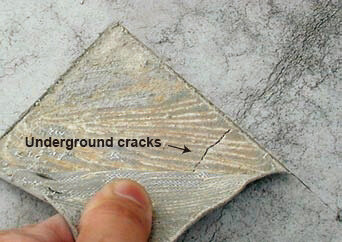

ARONCOAT SQ followed cracks as big as 1.0 mm in width without fail and maintained excellent coverage of the movement of underlying cracks even after 15 years.

Amount of top coat wear

Coverage and following of underlying cracks by ARONCOAT SQ.

Inquiries

- Department in charge

- Construction Materials and Civil Engineering Department

- Phone number

- 0120-557-947

*9:00 am - 5:00 pm (except weekends and holidays)